December News

SEA LOCK RESTORATION - Report by Michael Elliott - 29th December 2020

On the fifth day of Christmas, we were greeted at Sea Lock, not by five gold rings, but by five geese a-laying (down). That kept them out of the bitter wind. The task of the day was to re-arrange the scaffolding around the museum to give access for creosoting another part of the building. This was completed at the cost of numb fingers and toes all round.

On the fifth day of Christmas, we were greeted at Sea Lock, not by five gold rings, but by five geese a-laying (down). That kept them out of the bitter wind. The task of the day was to re-arrange the scaffolding around the museum to give access for creosoting another part of the building. This was completed at the cost of numb fingers and toes all round.

|

In parallel, a man in a digger, yours for £23,000, worked at scraping the soil and mud off the track. Apparently this work is easier in the rain, and where nature failed to provide, the canal obliged. This effort will prepare the track surface for a gravel finish, improving the alternative access route to the buildings at Sea Lock. |

|

ROSEMOOR RESTORATION - Report by Michael Elliott - 16th December 2020

There was an inauspicious start to the working party, as torrential rain had flooded the main road from Bideford to Torrington and the police turned people back. So most of the volunteers arrived on site an hour late. However, the delay meant that the rain stopped shortly after our arrival.

There was an inauspicious start to the working party, as torrential rain had flooded the main road from Bideford to Torrington and the police turned people back. So most of the volunteers arrived on site an hour late. However, the delay meant that the rain stopped shortly after our arrival.

Work continued at the tucking mill, exposing another step complete with side holes, and exposing more of the immovable tree stump. Two other tree stumps were tackled, one near the canal side mixed in with a lot of mud and lumps of ancient ironwork, and the other growing on top of a wall. All three stumps will be there to great us in the New Year.

Meanwhile, work on the lime kiln wall is more or less completed as far as can be reached safely without raising the scaffolding.

To round off the day a festive bring-and-share lunch was enjoyed at the Lime Kiln Arms.

Anyone wishing to volunteer should contact the Project Manager, Ian Harrison (tel.01237- 475707) or Treasurer, Tony Barnes (tel. 01237-473801) for up-to-date information.

SEA LOCK RESTORATION - Report by Michael Elliott - 15th December 2020

A cold and misty morning greeted us at Sea Lock, and a pallet of bricks in the wrong place. It soon warmed up in the winter sun, as we set about moving the bricks, mixing mortar and rebuilding the wharf wall: first the back edge, then the front, and finally the middle, the drain through the wall providing a handy stone-cleaning service. Space is now running out for rebuilding this section of the wall. Earth will soon need to be stripped away to expose the next section, now the bricks are out of the way.

A cold and misty morning greeted us at Sea Lock, and a pallet of bricks in the wrong place. It soon warmed up in the winter sun, as we set about moving the bricks, mixing mortar and rebuilding the wharf wall: first the back edge, then the front, and finally the middle, the drain through the wall providing a handy stone-cleaning service. Space is now running out for rebuilding this section of the wall. Earth will soon need to be stripped away to expose the next section, now the bricks are out of the way.

|

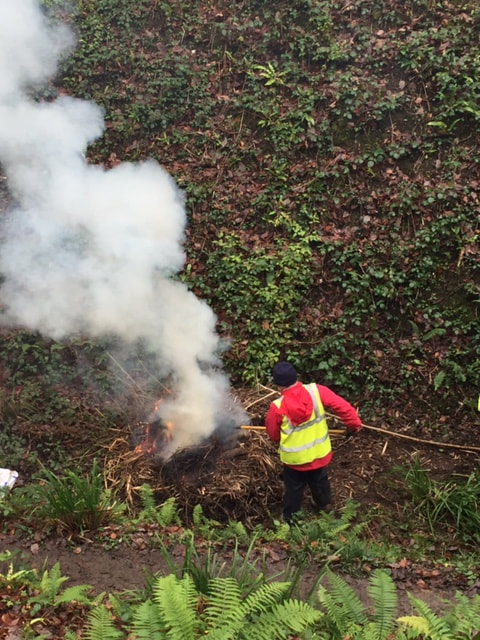

VOLUNTEER REPORT by Tony Barnes - 9th December 2020 The venue today was at Furzebeam along the permissive path granted by the Clinton Estate. Six stalwart volunteers turned up complete with every possible tool for digging scraping, cutting, and burning and put them to good use as we cleared the towpath alongside the steepest section of the embankment to enable walkers to keep well away from the steep drop. Whilst this was being cleared by one team a second was breaking up the pile of quarry scrapings, now some 8 years old, and transporting barrowloads to the more muddy and uneven sections of the towpath. Hard work all round. The other task we had set ourselves was to burn the pile of cuttings stored under the roving bridge and this was successfully accomplished with a lot of smoke and fire. A careful watch was kept out for any hedgehogs, but none were present. |

|

Sufficient time allowed us to also clear the culvert under the diversion around the embankment failure and to survey the work done by Clinton to clear the fallen oak tree which had blocked the path, The forester had carves a neat seat into the end of the trunk, a welcome relief for the closest volunteer, in this case Clive. The many walkers passing by all expressed their appreciation of the work being done but did not join in despite the invitation. A good days work. |

ROSEMOOR RESTORATION - Report by Tony Nicholls - 2nd December 2020

General view of the site

Work continued on the lime kiln and tucking mill this week despite some heavy drizzle at times.

Several more courses of stone were laid on the wall and the corner buttress of the lime kiln. We will soon reach our target height for the repair and will then be able to turn our attention to the remainder of the wall and the main arch – provided our 'quarry' of stone holds out. Fortunately, this is still providing good quantities of dressed stone i.e. stone with at least one good face. We have unearthed a perfect key stone (possibly from the old bridge?) which we hope to use in the restoration of the main arch.

Several more courses of stone were laid on the wall and the corner buttress of the lime kiln. We will soon reach our target height for the repair and will then be able to turn our attention to the remainder of the wall and the main arch – provided our 'quarry' of stone holds out. Fortunately, this is still providing good quantities of dressed stone i.e. stone with at least one good face. We have unearthed a perfect key stone (possibly from the old bridge?) which we hope to use in the restoration of the main arch.

On the tucking mill, we are slowly exposing the foundation of the southern wall although this work is being impeded by the inevitable tree roots. As noted in previous reports, the building is much larger than we originally thought. We think we have also worked out the purpose of the 'slots' on either side of the internal flight of steps. Initially, we thought these had been constructed either to allow the ingress of water to the site or for drainage but we now think that they were intended to house baulks of wood as 'treads' to protect the edge of the steps. This would explain why the steps are so narrow. The photo shows the steps with two wooden 'treads' inserted.

Foundation of the southern wall

Steps with wooden treads in place

Working arrangements may vary in the immediate future as a result of the coronavirus epidemic. Anyone wishing to volunteer should contact Project Manager, Ian Harrison (tel.01237- 475707) or Treasurer, Tony Barnes (tel. 01237-473801) for up-to-date information.

SEA LOCK RESTORATION - Report by Michael Elliott - 1st December 2020

Work at Sea Lock this week initially focussed on building up the back of the wharf wall . A strong layer here is needed to hold back the pressure of earth and water behind the wall. This involved preparing old concrete blocks for recycling in the wall by chiselling old mortar off the blocks. This is good for the biceps, as the mortar is almost as hard as the concrete block. Work then moved to building up the front of the wall, including spanning a gap in the base of the wall that will be filled later. Soon more earth will need to be stripped off the top of the wall so we can progress further down the wharf side.

Work at Sea Lock this week initially focussed on building up the back of the wharf wall . A strong layer here is needed to hold back the pressure of earth and water behind the wall. This involved preparing old concrete blocks for recycling in the wall by chiselling old mortar off the blocks. This is good for the biceps, as the mortar is almost as hard as the concrete block. Work then moved to building up the front of the wall, including spanning a gap in the base of the wall that will be filled later. Soon more earth will need to be stripped off the top of the wall so we can progress further down the wharf side.