February News

WHAT A DIFFERENCE A DAY MAKES! Sea Lock report by Adrian Wills - 28th February 2024

With four of us working at Sea Lock on Tuesday 27th February 2024, a great deal of progress was achieved on repairing the upper wharf wall. Steve and Nick started the day by carrying over to where we left off working before, four newly cast copers that I had made a few days earlier. This was something of a delicate operation since the blocks were very ‘young’ and had not had long to set hard.

With four of us working at Sea Lock on Tuesday 27th February 2024, a great deal of progress was achieved on repairing the upper wharf wall. Steve and Nick started the day by carrying over to where we left off working before, four newly cast copers that I had made a few days earlier. This was something of a delicate operation since the blocks were very ‘young’ and had not had long to set hard.

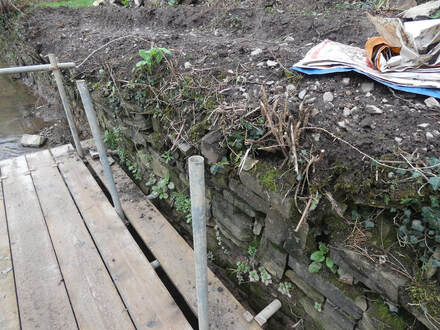

While they were laying these blocks, levelling them up and mortaring them permanently into place, Michael and I were preparing the next section of wall for rebuilding. As always, a great deal of loose stonework, roots and soil had first to be removed and cleaned out. Michael continued this task with enthusiasm whilst I then began rebuilding stonework and filling large cavities behind. Finding the right sized stones to fit holes proving to be habitually perplexing.

The morning had begun with a chilly start and a small measure of frost, but the temperature soon began to rise and working conditions were generally quite pleasant throughout the rest of the day. There was still a lot of surface water lying on and around the site making it very muddy and slippery.

By the end of the day another 2 metres of wall were topped and the scaffold lift on which we had been standing was ready to be dismantled and re-erected at the other end. Michael had uncovered a good length of wall which will be the next to be addressed and quite a length had been rebuilt.

Once the scaffold has been dismantled there is some repointing required to areas of the wall which are below the platform level, but these will also soon be repaired. This, of course, means getting down into the gloop yet again!

|

ONE MORE STEP ALONG THE ROAD (Wharf Wall!) Sea Lock report by Adrian Wills - 24th February 2024

Only a skeleton workforce of three working at Sea Lock on Tuesday 20th February 2024. Steve and Nick arrived ready to do battle once again and before long we were actively involved in various tasks. Steve and Nick attached the most recently cast coper to the backhoe of the Kubota and Nick duly drove it over to where we intended to lay it. I first had to move my Land Rover and trailer out of the way since I had parked it near where we wanted to unload the newly acquired stock of facing stone. Unfortunately, I couldn’t reverse the load to the exact spot since the trailer wheels were sinking into the very soft, wet surface. |

Having lowered the coper onto the wall, Steve spent time levelling it and getting it into the right place while Nick transferred the facing stone into the Kubota’s front-end loader and trundled it to where we actually wanted it. I was busy preparing the next section of wall to be renovated. There was an awful lot of soil and root to be removed which inevitably loosened facing stone. So, while Steve was trying to rebuild the wall, I was fully occupied in demolishing it!

Eventually, I reached a point in which I too could begin to rebuild and with Nick now keeping us supplied with mortar, repairs were progressing nicely.

|

There are still a number of issues to be addressed, namely some very large holes where stones have fallen out, problems arising from root penetration and deciding how much stonework has to be removed in order to reach a sound foundation. These issues are on-going and can only be overcome as they arise. Short of taking the remaining wall right down and starting again, the way we are progressing at the moment, although a compromise, is producing very pleasing and satisfying results. Slow but sure! |

A CHANGE OF PLAN Sea Lock report by Adrian Wills - 14th February 2024

The weather forecast for Tuesday 13th February 2024 was not good. Rain was expected to fall throughout the day so work at Sea Lock did not look too likely. To exacerbate the problem, two of the regular volunteers were not available and we were desperately short of good facing stone.

The forecast for the previous day was good so it was decided that Steve and I would have a little jolly to the quarry and select some more stone. Unfortunately, the nearest quarry had no suitable stone, so we had to journey to the next nearest, some 20 miles away.

The weather forecast for Tuesday 13th February 2024 was not good. Rain was expected to fall throughout the day so work at Sea Lock did not look too likely. To exacerbate the problem, two of the regular volunteers were not available and we were desperately short of good facing stone.

The forecast for the previous day was good so it was decided that Steve and I would have a little jolly to the quarry and select some more stone. Unfortunately, the nearest quarry had no suitable stone, so we had to journey to the next nearest, some 20 miles away.

When we arrived, we first had to have my Landrover and trailer weighed. This was not straightforward since I had to reverse the trailer onto the weighbridge and avoid hitting a very large excavator parked very close by.

|

From there we drove further into the quarry looking for the type of stone we wanted. This meant wiggling around various obstacles and through several muddy pools of water, having no idea how deep they were or whether there were any large stones concealed beneath the surface. However, all turned out well and we eventually pulled up alongside a pile of stones which looked promising.

Selecting and picking out stones from a big pile is slow and difficult. The stones were covered in mud and were very slippery as well as many being very heavy. We eventually had a reasonable quantity in the trailer and decided that we had had enough for the day so back to the weighbridge and then headed for home. After all our efforts, the load was only 1.6 tons, but it is sufficient to keep us going for a while. Having arrived back at my house I got out the pressure washer and gave all the stones a good clean before driving down to where we want to use them. |

The forecasters got it right! Despite Monday being dry and bright, Tuesday was a grey and miserably wet day, certainly not right for working out of doors.

AND YET MORE OF THE SAME! Sea Lock report by Adrian Wills - 8th February 2024

There were only four of us working at Sea Lock on Tuesday, February 6th 2024 but never the less we managed to get a lot done. Michael started the day by removing more overburden from the top of the upper wharf wall, Nick resumed his role of ‘head mortar-mixer and supplier’, while Steve and I got on with laying more stones.

There were only four of us working at Sea Lock on Tuesday, February 6th 2024 but never the less we managed to get a lot done. Michael started the day by removing more overburden from the top of the upper wharf wall, Nick resumed his role of ‘head mortar-mixer and supplier’, while Steve and I got on with laying more stones.

We are getting desperately short of good facing stone and are planning to visit the local quarry next week to replenish our stock. In the meantime, we were scrabbling about searching for suitable stones amongst the pile of ‘uglies’, of which we have plenty.

After spending some time and considerable energy Michael, joined by Nick, set about dismantling the section of scaffolding that was no longer needed and extended the lift at the other end, where we were next to work.

We were unable to lay the coper that I had cast a few days before since we hadn’t brought the wall up high enough. However, by the end of the day we had reached the point where we can now lay three more. I just have to cast them first!

|

We had been very lucky with the weather whilst we worked, it being dry and relatively calm. However, the wind could be heard in surrounding trees blowing increasing strongly. Having finished building for the day, we covered over all the new masonry with plastic and went home. Covering the work proved fortuitous since it rained very heavily that night and the EA issued several flood warnings for the area. |

ROSEMOOR RESTORATION REPORT by Tony Nicholls - 7th February 2024

A good turnout of volunteers this week meant that we were able to make good progress across the Rosemoor site.

Our main focus was to continue with the capping of the east wall of the upper basin. We have reached the difficult corner of the wall where it returns and the basin widens and this required a bespoke piece of formwork which our resident carpenter prepared off site. This proved to be a perfect fit and was soon locked into place on the wall. The shuttering from last week’s capping was released and re-installed lower down the wall to extend the capping by a further five metres or so. Our mixing team was then kept busy making the many barrowloads of concrete required to fill the waiting moulds. As can be seen from the photos, the finished capping laid last week looks very attractive.

A good turnout of volunteers this week meant that we were able to make good progress across the Rosemoor site.

Our main focus was to continue with the capping of the east wall of the upper basin. We have reached the difficult corner of the wall where it returns and the basin widens and this required a bespoke piece of formwork which our resident carpenter prepared off site. This proved to be a perfect fit and was soon locked into place on the wall. The shuttering from last week’s capping was released and re-installed lower down the wall to extend the capping by a further five metres or so. Our mixing team was then kept busy making the many barrowloads of concrete required to fill the waiting moulds. As can be seen from the photos, the finished capping laid last week looks very attractive.

Preparing the formwork

Installing the curved former

|

At the other end of the site, we carried on with the excavation of the chamber at the corner of the lime kiln. We have not had the resources to maintain this while we have been working on other areas and the cobbled floor has disappeared under a layer of mud and leaf mould. Part of the earth bank had also collapsed and we have now removed this spoil. The earth here is thick and clay-like so the work is strenuous. Footnote: when we removed the shuttering from last week’s capping we found what we think are a set of duck footprints in the concrete. Clearly, the local wildlife is anxious to leave its mark for posterity! Working parties are generally held every Wednesday morning, meeting in the main car park at RHS Rosemoor, Torrington at 9.30am. Please contact Project Manager, Ian Harrison (tel.01237- 475707) for more information. |

Capped wall upper basin

|

Working on the chamber

LIKE A GIANT JIGSAW PUZZLE Sea Lock report by Adrian Wills - 1st February 2024

Building walls is a relatively simple exercise, especially if using bricks or concrete blocks. Using random stone is a little more perplexing but less so if starting from a level and stable foundation.

Building walls is a relatively simple exercise, especially if using bricks or concrete blocks. Using random stone is a little more perplexing but less so if starting from a level and stable foundation.

Restoring deteriorating wharf walls is a completely different ball-game. Like a jigsaw puzzle finishing the edges is straight forward – the coping ‘stones’ have regular square and flat surfaces. Filling holes and gaps where stone and mortar has fallen out is another matter entirely. Just like a jigsaw, finding the right piece to fill a gap can be a nightmare. Facing stone is so often too long, too short, too thick, too thin or simply just not the right shape.

Sometimes, carefully chipping away at an awkward stone’s face, with a hammer, can produce a usable piece but it is not uncommon for that stone to shatter into what is then only usable as back-fill. – very irritating! It is frequently necessary to engage the services of the large petrol-driven stone-cutting angle grinder on site. Starting it is sometimes a bit of a trial and then there is all the dust and noise it creates. Such is life!

Sometimes, carefully chipping away at an awkward stone’s face, with a hammer, can produce a usable piece but it is not uncommon for that stone to shatter into what is then only usable as back-fill. – very irritating! It is frequently necessary to engage the services of the large petrol-driven stone-cutting angle grinder on site. Starting it is sometimes a bit of a trial and then there is all the dust and noise it creates. Such is life!

On Tuesday, January 30th 2024, Steve, Nick. Michael and Tony arrived ready to start work again on the ‘Jigsaw’. It was my intention to carry 2 copers over to the wall, carried by the Priestman crane whilst Nick prepared a load of mortar and Steve cleared the place where the blocks were to be laid.

Michael and Tony got to work removing more debris and overburden from the top of the wall, (inadvertently knocking some down into the canal), whilst Steve and I attached lifting strops to the blocks. Once again, the crane’s battery had insufficient charge to start the engine so we resorted to jump-staring it from the Kubota’s battery. Eventually we got it running and I trundled it over to where the blocks were stacked, hoisted them up and began driving over to the wall.

This proved to be a very slow process. The crane’s engine was running sweetly but the steering mechanism was being particularly cantankerous (lack of regular use!). Eventually I coaxed the crane and its load, to where we needed it to be and lowered the blocks into place. While I slowly drove the crane, back to its parking place Steve and Nick set the blocks permanently into place.

Having achieved this I actually continued doing some stone-wall building. Steve spent much of the rest of the day on his knees while he repaired and repointed a number of cavities low down on the wall. This didn’t do his knees or back a great deal of good! Nick varied his time between mixing and delivering more mortar, back filling behind the blocks and levelling the towpath with the Kubota.